The Ultimate Tips for Pipe Maintenance From American Plastics LLC Texas

Wiki Article

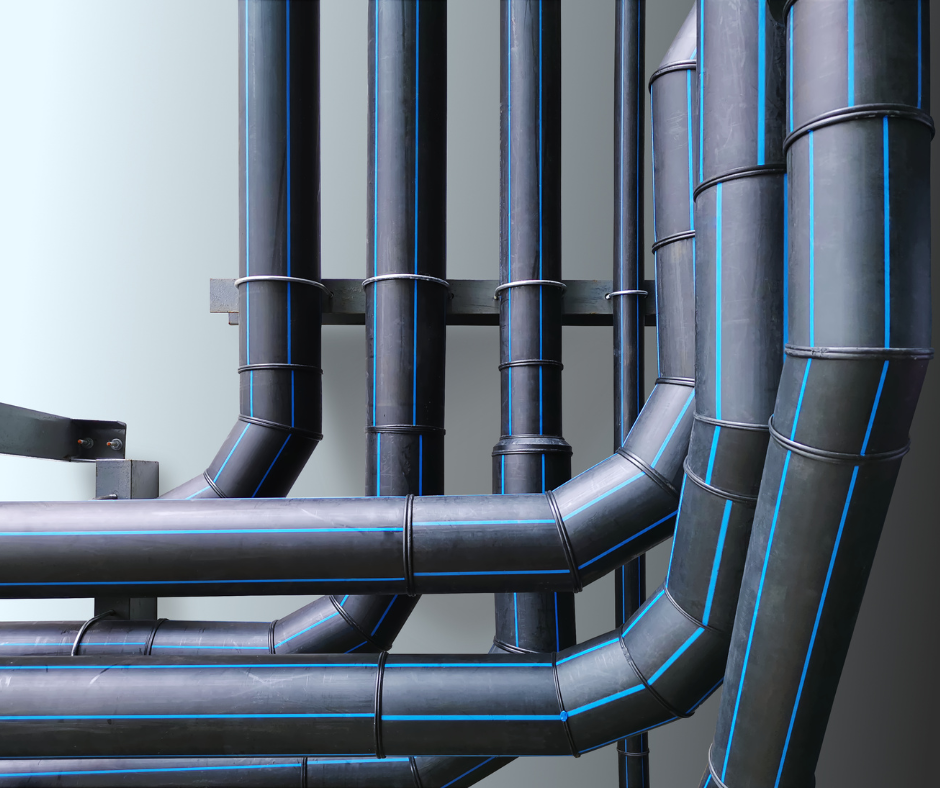

Enhance Your construction Tasks With Trusted Pipe Materials Essentials

In the construction industry, the option of pipe materials plays a vital function in task success. Quality materials can considerably impact longevity and safety. Different pipeline kinds offer distinct functions, from drain to water system. Understanding these fundamentals is important for performance. However, lots of overlook the nuances of choosing the ideal parts and vendors. Discovering these variables can result in much better results for any type of construction venture. What should be thought about following?Understanding the Significance of High Quality Pipe Products

While numerous may ignore the value of quality pipe supplies, their role in different construction and plumbing projects can not be overemphasized. The integrity of a project frequently depends upon the integrity of materials made use of, specifically pipelines. High-grade pipelines guarantee resilience, reducing the likelihood of leaks and failings that can cause costly repair services. In addition, they contribute to the overall safety of pipes systems, stopping dangerous scenarios that might develop from substandard items.Buying top quality pipeline materials also improves the effectiveness of installations. Well-manufactured pipelines meshed seamlessly, minimizing labor time and prospective difficulties during setting up. Additionally, they frequently come with guarantees that give assurance for specialists and homeowners alike. In a sector where safety and efficiency are critical, picking the right pipe products is not merely a preference; it is a necessity that influences the longevity and success of construction ventures.

Sorts Of Pipe Materials and Their Applications

The option of pipeline products is essential for guaranteeing the efficiency and durability of different applications. Various products, such as Copper, steel, and pvc, each deal special residential or commercial properties that fit certain needs. Comprehending these materials and their appropriate usages can substantially influence the efficiency of pipes and industrial systems.Common Pipe Material Kind

Pipe materials play an important duty in different construction and pipes applications, each type offering unique buildings fit for specific features. Typical pipe materials consist of PVC, which is immune and light-weight to corrosion, making it suitable for drainage and irrigation systems. Copper pipes are renowned for their durability and thermal conductivity, often used in water supply lines. American Plastics LLC Texas. Steel pipes, stainless or particularly galvanized, are preferred for their stamina and durability, ideal for high-pressure applications. PEX, or cross-linked polyethylene, offers versatility and convenience of setup, mainly made use of in property pipes. Each material type addresses details needs, ensuring that construction and plumbing projects accomplish exceptional efficiency and longevity while adhering to market criteria

Application-Specific Pipe Makes Use Of

Recognizing the certain applications of different pipeline products boosts decision-making in construction and pipes jobs. Various products offer distinctive purposes based upon their residential properties. PVC pipelines are generally used in drainage systems due to their light-weight and corrosion-resistant nature. Copper pipelines are preferred for supply of water lines, as they are resilient and possess antimicrobial buildings. In commercial setups, steel pipelines are favored for their stamina and ability to manage high-pressure applications. PEX pipes offer flexibility and simplicity of installation for property pipes. Each kind of pipe product is tailored for details demands, making it important for specialists to pick the right choice to guarantee effectiveness, safety, and longevity in their jobs.Important Pipeline Fittings for Effective Installments

Elbows enable directional adjustments, while tees branch off into additional lines, enhancing system adaptability. Combinings assure safe and secure links between pipeline areas, preventing leakages and maintaining architectural integrity. Reducers play a crucial duty in shifting between different pipe diameters, supporting effective flow and lowering stress loss.

The selection of high quality pipeline fittings is necessary, as subpar materials can lead to rust, leakages, and system failures. Consequently, purchasing dependable fittings not just boosts setup performance however likewise adds to the longevity and performance of the whole piping system.

The Role of Shutoffs in construction Tasks

Valves offer an important feature in construction tasks, working as control mechanisms that control the circulation of fluids within piping systems. They are vital for ensuring safety and performance in different applications, from supply of water to chemical handling. Various kinds of shutoffs, such as gate, globe, and ball shutoffs, offer unique benefits, enabling specific control over flow prices and pressure degrees.Along with flow guideline, valves play a crucial function in preventing heartburn and safeguarding systems from overpressure scenarios. Their installation can substantially impact the general functionality of a job, affecting upkeep requirements and functional expenses.

Furthermore, the choice of proper valve products is crucial, as they need to stand up to details environmental conditions and liquid characteristics. Appropriate valve combination within construction designs not only improves system reliability but also contributes to attaining compliance with market requirements and policies, inevitably bring about effective job conclusion.

Just how to Select the Right Pipe Supply Vendor

Selecting the right pipe supply vendor requires mindful consideration of a number of key factors. It is crucial to assess the integrity of the vendor, review the quality standards of their items, and contrast their rates and solutions. These actions will help guarantee that the picked vendor satisfies project requirements efficiently.

Evaluate Vendor Integrity Elements

When evaluating potential pipe supply suppliers, it is vital to consider various factors that add to their dependability. To start with, the supplier's experience in the sector can give insight right into their ability to fulfill job needs. American Plastics LLC. In addition, identifying their financial stability is vital, as it suggests their capacity to satisfy lasting contracts. Timeliness in distribution and responsiveness to questions are also substantial indicators of a vendor's dependability. Additionally, taking a look at consumer reviews and reviews can offer beneficial perspectives on their service background. Recognizing their supply chain monitoring techniques can disclose their capacity to take care of unanticipated disruptions. By thoroughly thinking about these variables, construction professionals can make informed choices when choosing pipe supply vendors for their jobsExamine Item High Quality Criteria

Assessing item top quality criteria is crucial for selecting the best pipeline supply supplier, as the sturdiness and efficiency of pipes straight affect task success. It is vital to examine the products utilized in producing pipelines, as premium materials ensure longevity and resistance to ecological factors. Vendors need to supply qualifications and conformity with market standards, which can show reliability and security. In addition, evaluating item specs, such as stress ratings and corrosion resistance, offers understanding into the viability of pipelines for specific applications. Carrying out extensive research on a vendor's online reputation, including customer evaluations and testimonials, can additionally assist assess the high quality of their items. Ultimately, focusing on high quality criteria will add to overall project efficiency and efficiency.Compare Prices and Providers

How can one properly compare prices and solutions amongst pipeline supply vendors? To make an informed decision, it is important to gather comprehensive quotes from numerous distributors, guaranteeing that comparable items and amounts are being contrasted. Evaluating the overall expense, consisting of shipping and any type of added costs, is vital (American Plastics LLC Texas). Additionally, analyzing the variety of solutions supplied-- such as shipment choices, customer support, and return policies-- can affect general fulfillment. It is additionally advantageous to read client evaluations and testimonies to assess integrity and service quality. Finally, think about the supplier's track record within the market, as a well-established vendor may provide far better assistance and consistency. By taking these actions, one can pick a pipe supply supplier that lines up with both budget plan and project demandsExpense Savings Via Reliable Pipeline Products

Reputable pipeline materials offer as a cornerstone for cost financial savings in both industrial and property projects. By picking top quality materials, specialists can minimize the threat of failures and leaks, which frequently bring about expensive fixings and job hold-ups. Purchasing trusted pipelines ultimately minimizes upkeep expenses over time, as these products normally offer better toughness and long life.Additionally, dependable vendors often offer affordable rates, enabling builders to stay within budget plan without compromising top quality. Bulk acquiring options and price cuts for lasting collaborations further improve economic performance.

Furthermore, using reputable pipe materials can streamline setup processes, as these products are made for compatibility and simplicity of usage. This effectiveness not just saves labor expenses but additionally shortens project timelines. On the whole, taking on dependable pipe products is a critical method that promotes significant expense savings while making certain task stability and customer complete satisfaction.

Ideal Practices for Maintaining Pipe Honesty in Projects

Reliable maintenance of pipeline stability is essential for the success of any kind of construction task. To attain this, normal inspections are necessary; these need to consist of visual assessments and stress screening to identify any kind of weaknesses. Proper setup check this site out strategies should be followed to stop future issues. Utilizing quality products that are fit for the certain project atmosphere will additionally enhance longevity.In addition, implementing an upkeep routine can aid in proactively resolving potential concerns before they intensify. This should include regular cleansing to stop obstructions and corrosion, alongside checking for leaks. Training personnel on the value of pipe honesty and secure handling practices guarantees that all group participants add to keeping the find out here now system.

Finally, documenting all maintenance activities provides a clear history that can educate future projects. By sticking to these best practices, construction teams can secure the longevity and integrity of their piping systems, ultimately adding to task success.

Regularly Asked Concerns

What Are the Ecological Impacts of Various Pipe Products?

Different pipe materials have differing environmental impacts. PVC can launch damaging chemicals throughout production, while steel pipelines may need energy-intensive mining. Eco-friendly options offer sustainability however might do not have sturdiness compared to standard materials.How Do Weather Condition Conditions Affect Pipe Installation?

Weather considerably influence pipe setup, as severe temperatures, precipitation, and wind can impact material stability, setup strategies, and worker safety. Appropriate planning and modifications are vital to guarantee successful installation under varying ecological conditions.

What Accreditations Should Pipeline Products Have?

Pipeline products must possess accreditations such as ASTM, ISO, and ANSI. These verify compliance with market requirements, security guidelines, and high quality assurance, ensuring that the materials utilized are appropriate and dependable for construction projects.Can Recycled Materials Be Utilized in Pipe Production?

Yes, recycled products can be utilized in pipe manufacturing. Many firms integrate recycled plastics and steels right into their production processes, promoting sustainability while keeping quality and performance criteria crucial for different construction applications.How to Guarantee Conformity With Regional Building Codes for Pipelines?

To ensure compliance with neighborhood building regulations for pipes, one must look into particular regulations, seek advice from neighborhood authorities, acquire essential licenses, and use licensed materials while complying with installation techniques laid out in the relevant guidelines and criteria.

Report this wiki page